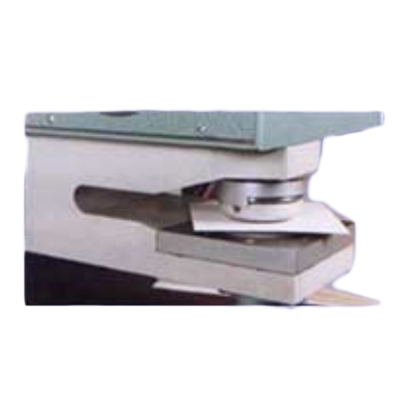

Print Surface Roughness Tester

Price 22000.00 INR/ Unit

Print Surface Roughness Tester Specification

- Equipment Type

- Print Surface Roughness Tester

- Classification

- Testing Equipment

- Application

- Quality control in printing processes

- Usage

- Laboratory

- Color

- Silver/gray

Print Surface Roughness Tester Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 20 Units Per Week

- Delivery Time

- 4 Week

About Print Surface Roughness Tester

This Print Surface Roughness-Smoothness Tester is immensely used for testing the smoothness of print surface under certain load conditions. It is intricately manufactured by using high-end machines as per the set quality norms. It is microprocessor controlled instrument available in various models and technical specifications. The test result generated with this tester has shown excellent correlation with print smoothness by using offset ink. Apart from this, Print Surface Roughness-SmoothnessTester is known for their unique features like robust and compact structure, low power consumption and trouble-free operation.

DESCRIPTION:

Print Surface Roughness/Smoothness Tester measure the roughness / smoothness as per the condition apply in the printing press nip at the moment of printing, by clamping the sample between a precise measuring head and a specially backing assembly with variable clamping pressure.

Roughness/Smoothness of a sheet of paper or board is a function of the rate at which air will pass between specified flat land and sheet of the paper or board tested under specified conditions. The property is termed roughness/smoothness if increasing numerical value indicates increasing roughness/smoothness.

The roughness/smoothness of the sample is calculated in micrometers on calibrated air flow meters (Rotameters).

ADVANTAGES:

Surface roughness is very much interest for good printing results. The layer of ink must be thicker than the roughness to give a good and glossy print. The amount of ink used is not only a cost but also influence the drying time and thus the risk is set off. With more ink there is also bigger risk for print through problems. When lamming paper with metal foil or with plastic film, the overall results depends very much on the surface roughness of the base paper used.

APPLICATIONS:

Used for writing / printing paper, newsprint, coated paper and other similar grade of paper.

TECHNICAL SPECIFICATION:

| Measuring Range : | 0.9-6 m |

| Contact Pressure : | Variable (5/10/20 Kgf / cm2) |

| Air Pressure : | Regulated from 0 to 3 wg / inches |

| Air Requirement : | 0-7 kg/cm2 compressed air |

| Selection Switch : | Rotary |

| APPLICABLE STANDARDS : ASTM D 774, ISO 2758, ISO 2759, ISO 2960 | OPTION: As Per Customer Requirement | |||||||

| ||||||||

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

|

GLOBAL ENGINEERING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry