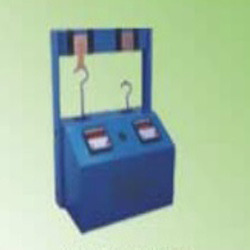

Tube/Core/Cone Collapsing Tester

Tube/Core/Cone Collapsing Tester Specification

- Temperature

- 10C to 40C operating

- Frequency

- 50 Hz

- Mounting Type

- Floor standing

- Interface Type

- RS232 (optional)

- Features

- Heavy-duty construction, overload protection, precise measurement

- Resolution

- 0.1 kg

- Accuracy

- 1% of full scale

- Test Range

- 0 1000 kg

- Hardness

- Industrial-grade steel clamps and base

- Response Time

- Instantaneous digital display

- Max Height

- 600 mm

- Power Supply

- 230 V AC, 50 Hz

- Specimen Size

- 25 mm to 600 mm length, up to 100 mm diameter

- Equipment Type

- Tube/Core/Cone Collapsing Tester

- Automation Grade

- Semi-Automatic

- Humidity

- Up to 85% RH

- Application

- To determine the collapsing strength of cardboard tubes, cores and cones

- Number of Specimens

- Single specimen at a time

- Display Type

- Digital LED

- Measuring Range

- 01000 kg

- Operating Voltage

- 230V AC

- Port Size

- 25 mm

- Gas Pressure

- 6-8 kg/cm2

- Usage

- Paper tube, core, and cone strength testing

- Capacity

- 1000 kg

- Machine Weight

- Approx. 90 kg

- Test Speed

- 12.5 mm/min (typical)

- Test Width

- 100 mm

- Test Stroke

- Up to 200 mm

- Control Mode

- Microprocessor based

About Tube/Core/Cone Collapsing Tester

Collapsing strength tester is designed in sucha manner that gradually increasing force is generated & applied on thesurface of carriers. The sharp collapsing point can be easily detected on adial and a suitable reading can be taken.

Capacity:1000 Kgf

Least Count:9.15

Accuracy:2%of full scale

Test AdoptersOD: Upto 100 mm

Air Pressure:6 Kg/cm2

Superior Build & Performance

Constructed with heavy-duty, powder-coated mild steel, this tester ensures exceptional longevity and stability during repeated use. The reliable hydraulic or manual clamping system secures specimens firmly, providing accurate, reproducible results across a broad spectrum of test conditions.

Advanced Control & Precision

Featuring a microprocessor-based control mode and a user-friendly touch keypad, the tester delivers precise measurements with an accuracy of 1% of full scale and a resolution of 0.1 kg. Safety is prioritized through overtravel and overload protection features, guaranteeing optimal operator and equipment safety.

Comprehensive Compliance & Data Handling

Designed in accordance with ASTM D7263 and IS 7028 standards, the tester supports extensive memory storage for up to 200 results. It allows seamless data transfer and printing, aiding in efficient test documentation and analysis for traceability and regulatory compliance.

FAQ's of Tube/Core/Cone Collapsing Tester:

Q: How does the Tube/Core/Cone Collapsing Tester operate?

A: This tester operates using a touch keypad, with microprocessor-based control for precision. You can select between hydraulic or manual clamping of the specimen and choose your display units in kg or Newtons. The digital LED shows instantaneous results, and all operations are safeguarded by overload and overtravel cut-off.Q: What materials and sizes can be tested on this machine?

A: The tester is designed for cardboard tubes, cores, and cones with length from 25 mm to 600 mm and up to 100 mm in diameter. It features interchangeable specimen holders to accommodate different sizes, making it versatile for varied testing requirements.Q: Where is the Tube/Core/Cone Collapsing Tester commonly used?

A: It is primarily used in paper tube and packaging manufacturing units, quality assurance labs, and research institutions to evaluate the structural strength of tubes, cores, and cones, ensuring product reliability and compliance with international standards.Q: What is the process for conducting a collapse strength test?

A: Simply place the specimen in the appropriate holder, secure it with the hydraulic/manual clamp, set the test parameters via the touch keypad, and start the test. The machine applies pressure at a set speed (typically 12.5 mm/min) until specimen failure, displaying results instantly and storing them in memory.Q: When should calibration and maintenance of the tester be performed?

A: To ensure ongoing accuracy, calibration should be carried out periodically as per industry guidelines or after high-usage intervals. The machine is delivered with a calibration certificate for initial setup. Maintenance involves checking clamps, ensuring proper hydraulic function, and cleaning the display and controls regularly.Q: What benefits does this tester provide manufacturers?

A: It offers precise, repeatable measurements, customizable data output, strong safety features, rugged construction, and compliance with international standards, optimizing process control and quality assurance in tube and core production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Testing Instruments Category

Bopp Tape Shear Tester

Price 22000 INR / Unit

Minimum Order Quantity : 1 Unit

Application : Adhesive Tape Static Shear Strength Testing

Machine Weight : Approx. 15 kg

Features : Corrosion Resistant; Rigid Construction; Simple Loading Weights

Power Supply : Not Required (Manual Operation)

Torque Tester

Application : Cap, bottle, and closure torque measurement

Machine Weight : 18 kg

Features : Peak/Continuous Reading, Overload Protection, Data hold/Export

Power Supply : 220V AC, 50Hz

Drop Tester

Application : Drop Impact Testing for Packaging

Machine Weight : Approx. 100 kg

Features : Adjustable drop height, dual column lift, flat and corner drop

Power Supply : AC 220V, 50 Hz

Tensile Strength Tester (Microprocessor Based)

Price 125000.00 INR / Unit

Minimum Order Quantity : 1 Set

Application : Industrial

Machine Weight : 140 Kilograms (kg)

|

GLOBAL ENGINEERING CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry